Processing

Streamlined Processes for Operational Excellence at Gendev

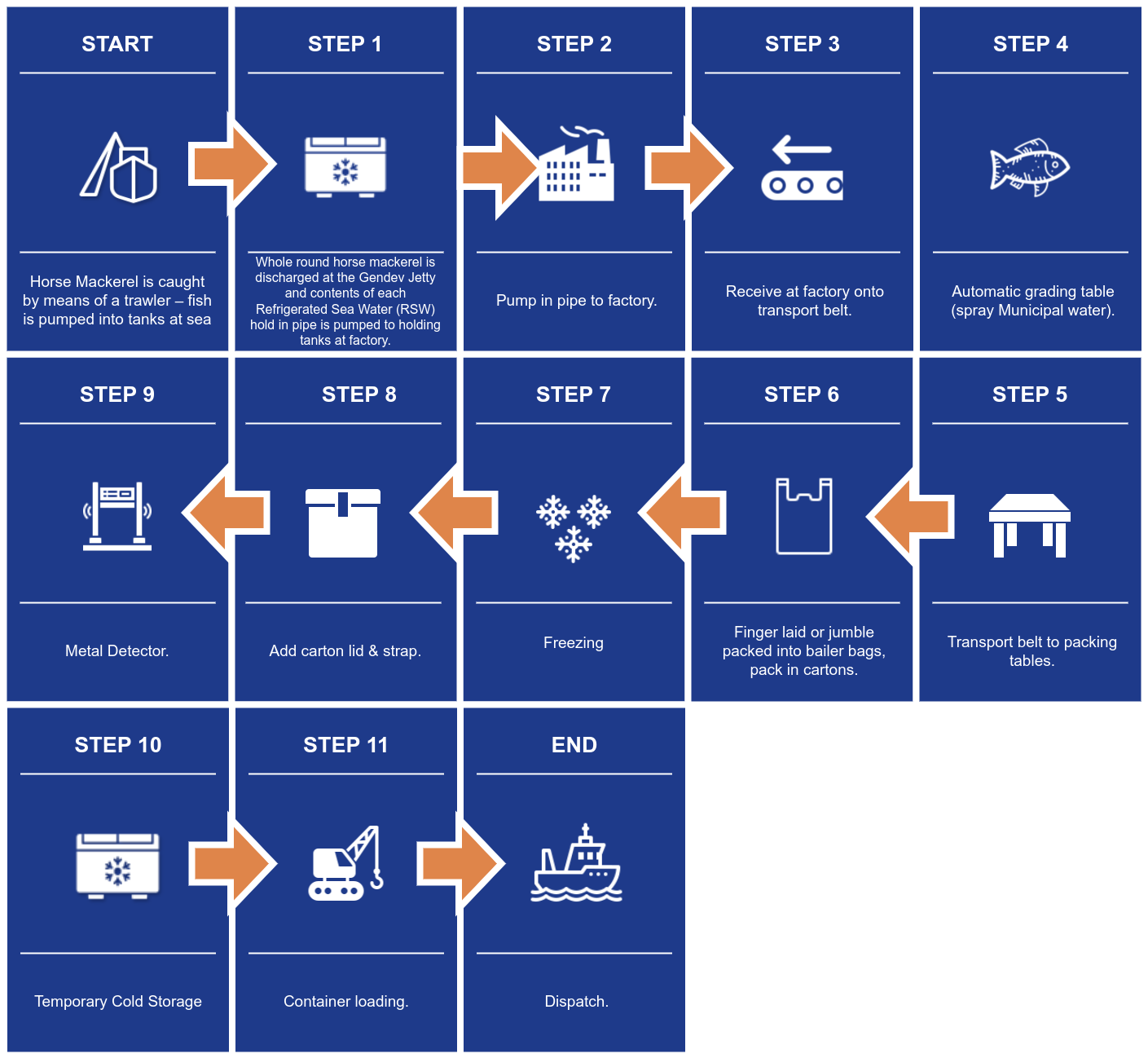

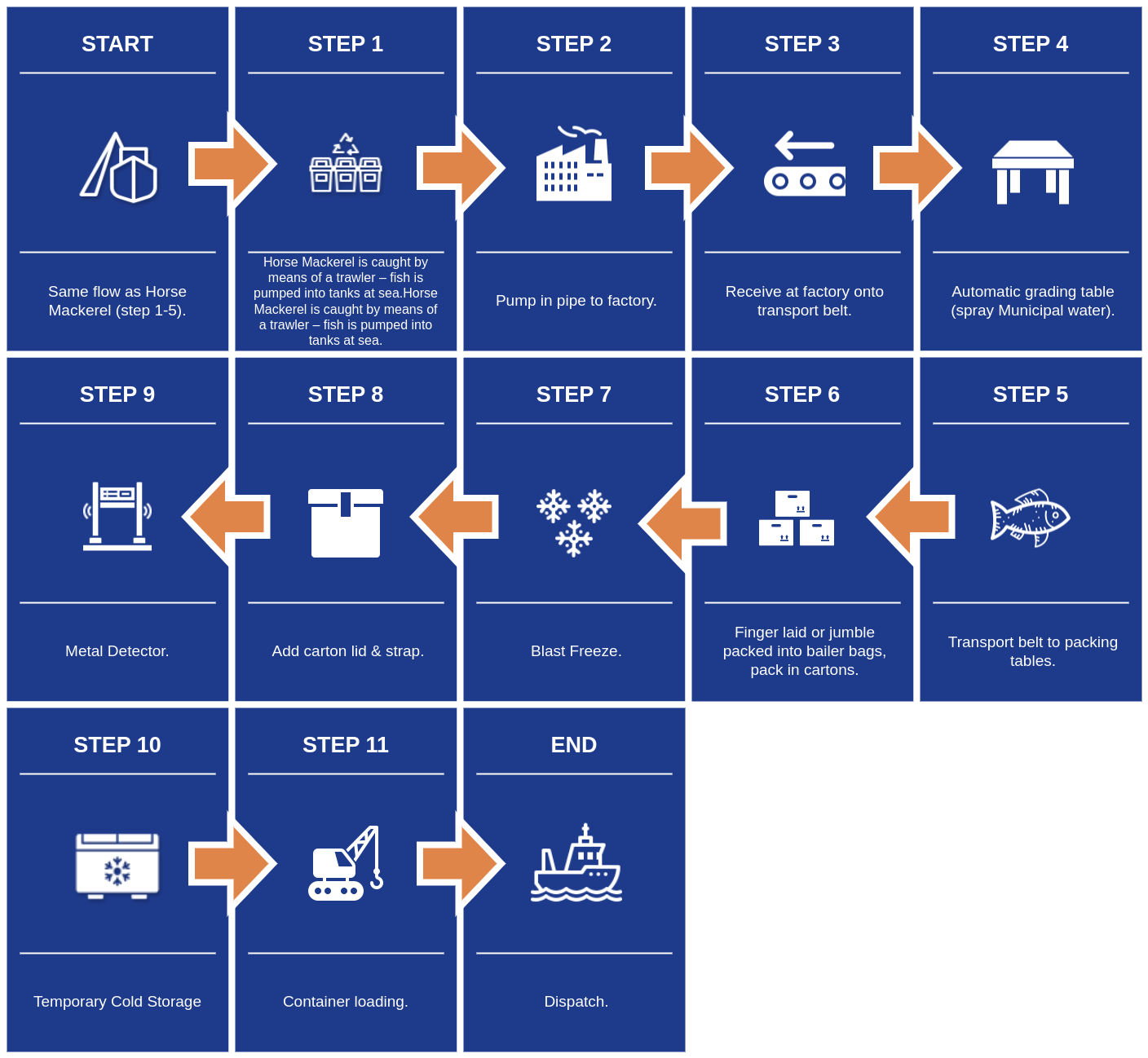

At Gendev, our Horse Mackerel operations are characterized by a comprehensive and meticulous approach to processing that ensures product quality, consistency, and customer satisfaction. Our grading process involves sorting the fish into six distinct sizes, ranging from 14Minus to 25+, based on length measured in centimeters (CM). This precision extends to our packing procedures, where we offer flexible packaging options tailored to meet specific customer needs, leveraging our land-based facilities to diversify our range, including 5kg, 10kg, 20kg, 30kg, and Bulk IQF configurations.

Our freezing capabilities are state-of-the-art, utilizing advanced blast freezers with a capacity of up to +/- 220 tons per day, complemented by a specialized spiral freezer capable of handling 20 tons per day across two shifts. Post-processing, our products are stored in our own cold store to maintain optimal freshness and quality, ensuring that our customers receive top-quality Horse Mackerel products every time.

In terms of technology, Gendev employs a unique jumble-packed approach for Horse Mackerel, enhanced by the Individual Quick Freezing (IQF) process using a spiral freezer, giving us a competitive edge in the market. Our commitment to quality is further underscored by our HACCP-approved facility, adhering to EU standards to guarantee product consistency and safety. We are also focused on continuous improvement and innovation, as demonstrated by our recent addition of an automated box folding machine to enhance operational efficiency.

For more information on our accreditations, certifications, and quality assurance measures, please refer to Jonas Lamek. We are constantly exploring opportunities for further process improvements and innovations to streamline our operations and uphold our commitment to excellence in Horse Mackerel processing.

"We provide high-quality and sustainable fish products while protecting the environment."

Our Processes

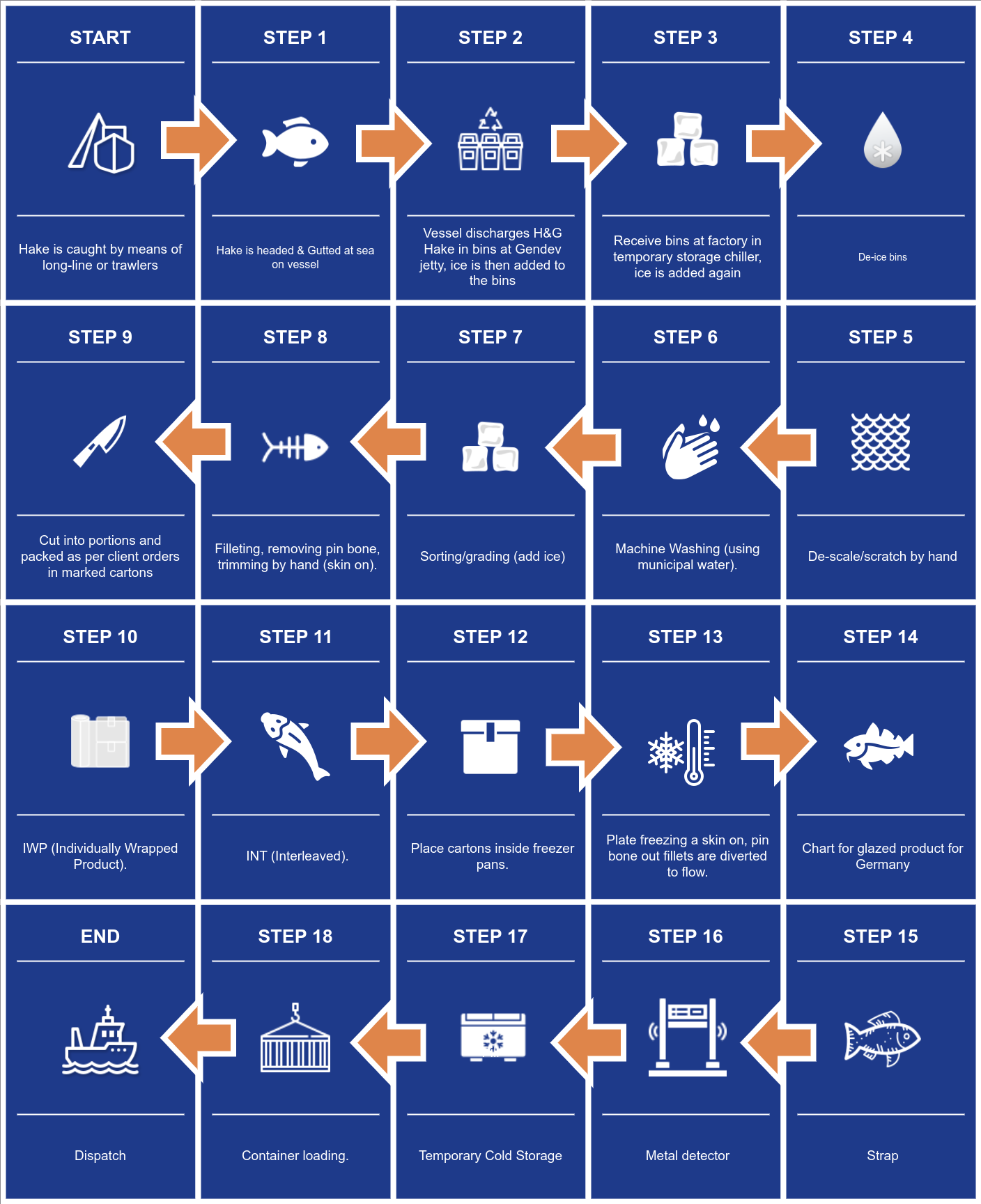

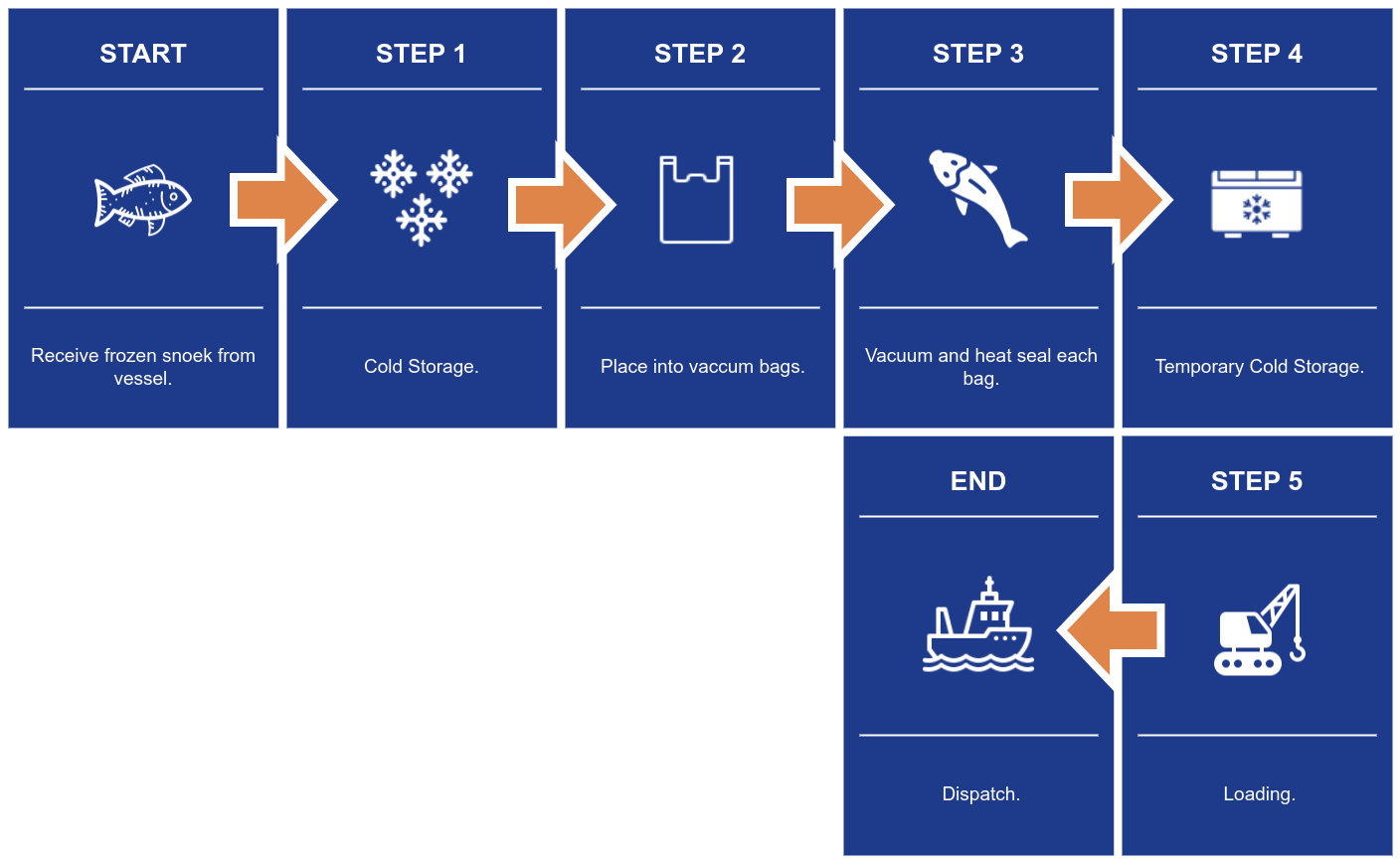

Quality checks are done in all of the processes to ensure products adhere to the requirements of the governing bodies.

Flow chart for frozen hake products (exports)

Flow chart for frozen skin on, pin bone out hake fillets (exports)

Flow chart for frozen horse mackerel products (exports)

Individually quick frozen (IQF) horse mackerel product

Flow chart for frozen snoek

From The Operations Managers Desk

Horse mackerel

Grading – we grade the fish into 6 different sizes. 14Minus, 16Minus, 16+, 18+, 20+ and 25+. The gradings are determined on the length of the fish. For example – 16+, is 16cm and bigger – 16Minus, is 16cm and smaller. Unit of measure is in CM.

Packing – We pack according to customer specs and needs. This is what makes land base more ideal. We can diversify our range of packaging. Currently we pack a 5kg,10kg(1x10kg), 20kg(2x10kg), 30kg(3x10kg), 20kg Bulk IQF, 10x1kg IQF.(IQF – Individual quick freezing).

Freezing – We freeze using blast freezers. We freeze up to +/- 220tons/day(24hours). We also use a spiral freezer – Capacity of 20tons/day (2shifts)

Storing – After processing, we have our own cold store for our products. For more information, please contact the relevant department.

Currently Horse Mackerel is jumble packed. The only process we have additional is the IQF. Spiral freezer. This gives us an edge in the market. Something unique to Gendev

We have a HACCP approved facility. This ensures that we pack according to EU standards

Our main goal is to create employment. We added an automated box folding machine to assist in faster and more effective folding of cartons. At this stage there is a lot off dreams we strive to, but we keep our focus on creating jobs and creating job security.